Flame Retardant and Smoke Suppressant

We provide a range of products containing the Kemgard® series of fire retardants produced by Huber Engineered Materials, an American manufacturer of inorganic chemicals.

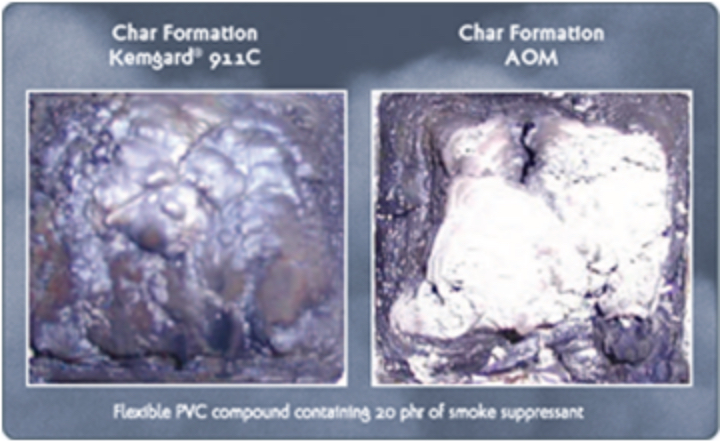

Kemgard® products contain an environmentally-friendly molybdenum-based flame retardant. This promotes char formation during combustion which suppresses flames and smoke.

These products have a core consisting of an inert material such as talc or calcium carbonate, which is coated with zinc molybdate, effectively shielding the polymer from heat and oxygen.

Kemgard® : Flame Retardants / Smoke Suppressants

Flame retardants and smoke suppressants are an additive that increases safety by reducing the emission of smoke and harmful substances to make products made of flammable materials such as plastic less flammable and to prevent harming health from them, when a fire breaks out.

Kemgard® is a cost-effective and highly functional flame retardant and smoke suppressant produced and sold by Huber Engineered Materials in US. It is an ideal solution to improve flame retardancy and smoke suppressants, mainly for vinyl chloride and epoxy resins.

For Rigid and Flexible PVC (Polyvinyl Chloride Resin)

- From pipe and fitting compounds in high rise buildings to panels and decorative materials used in today's building and construction markets to modern aircraft interior panels, the product that meets the most stringent smoke suppression requirements is Kemgard®.

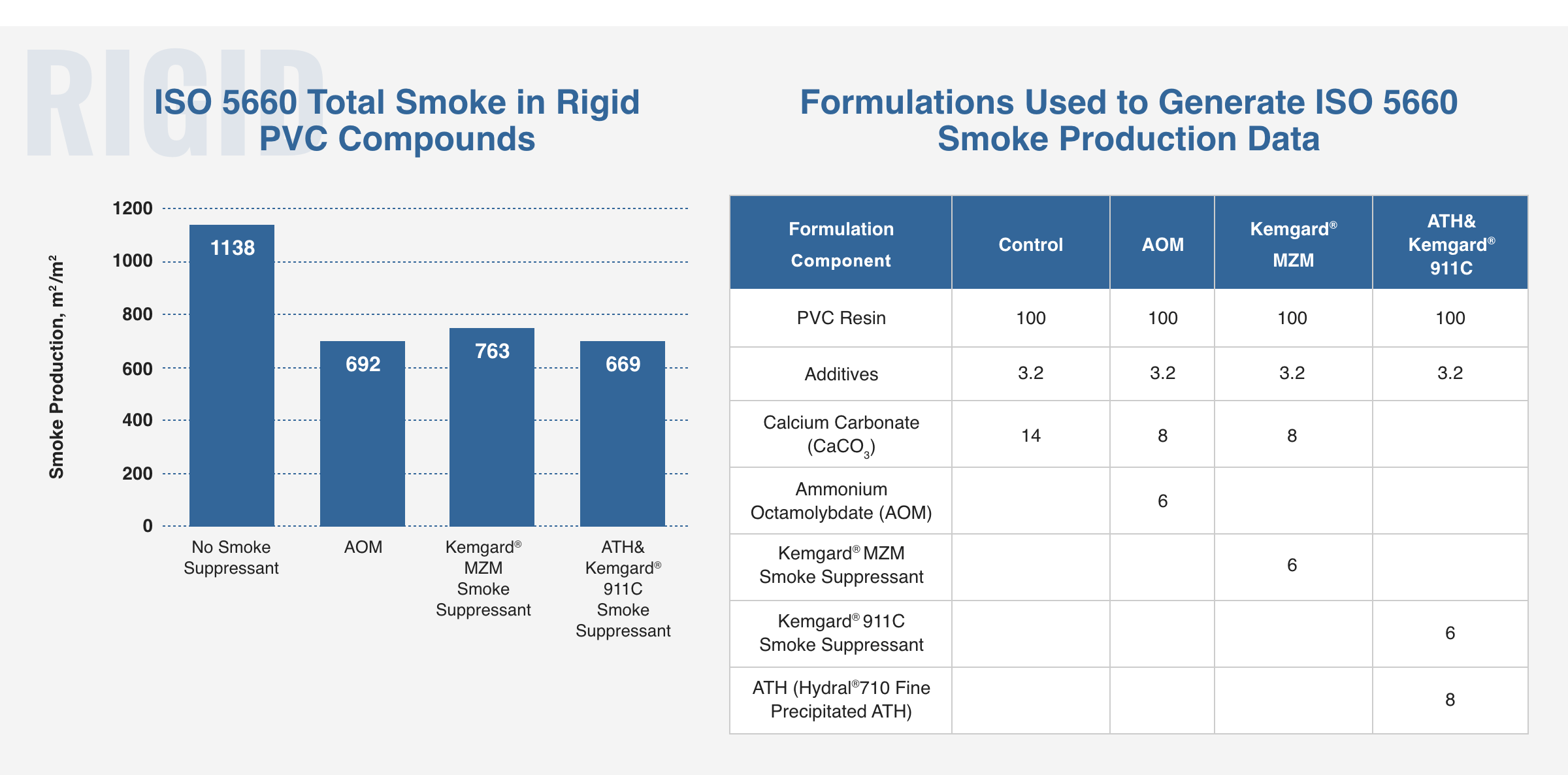

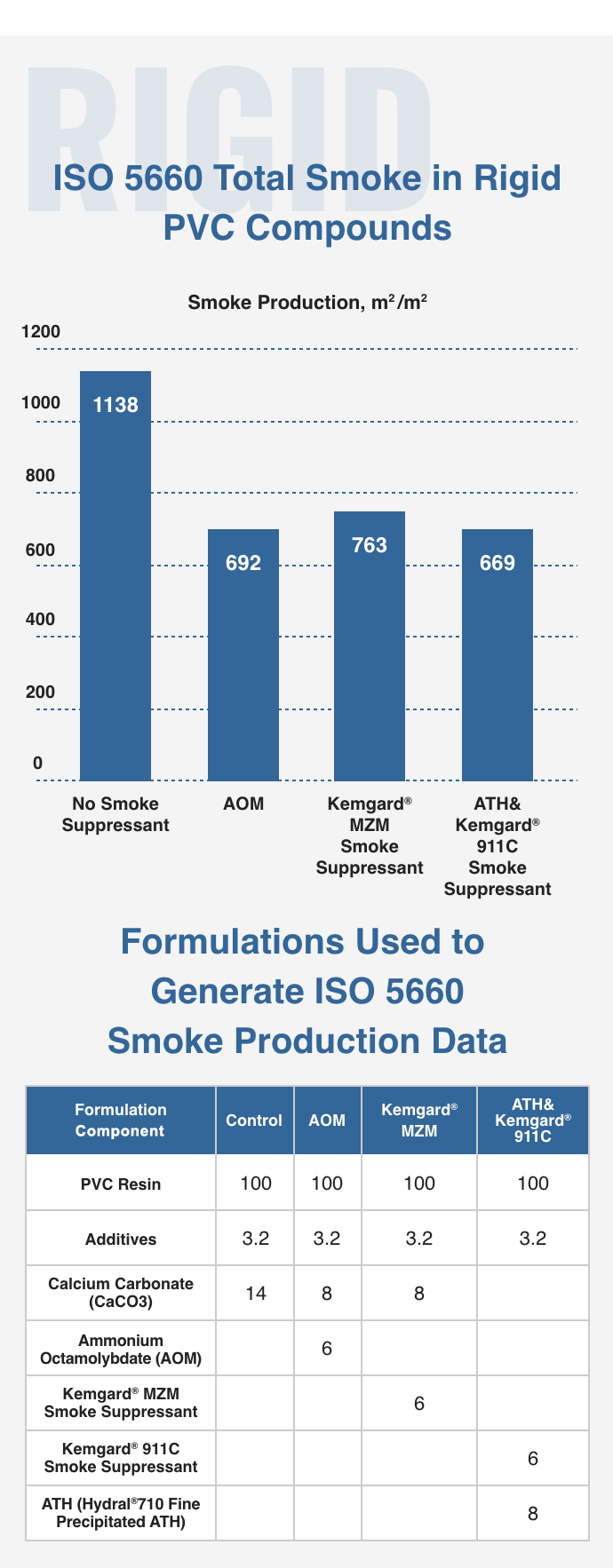

- Kemgard® is manufactured and sold using the patented technology that precipitates molybdate compound into inorganic core material. By maximizing the surface area of the active surface, this core-to-surface coating technology makes molybdic acid worked more efficiently at a lower cost than pure molybdate chemicals such as ammonium octamolybdate (AOM). Molybdic acid can be used with other materials in order to replace antimony oxide.

Features

- Suppressing heat and smoke by forming robust organic

- Patented molybdate technology

- “Coating” molybdic acid compound on inorganic core material

- Achieving lower cost for using ammonium octamolybdate (AOM)

- Possible to replace antimony oxide as the measure against the Specified Chemical Substance Hazard Prevention Regulations

Kemgard® Flame Retardants and Smoke Suppressants Lower Smoke Generation by Robust Char Formation

Kemgard® fire retardant additives influence the formation of a robust organic char, effectively insulating the polymer from the heat and oxygen source, thereby lowering heat and smoke release.

NBS Smoke Samples (For electric wire cable)

- ATH

- 60 phr

- Sb2O3

- 3 phr

- Stabilizer

- 7 phr

- Solutia 2148

- 20 phr

- FRP-45

- 20 phr

- smoke suppressant

- 20 phr

Huber's Kemgard® Products

| Physical Properties | Component | Applications | ||

|---|---|---|---|---|

| Kemgard® Products(White Powder Appearance) | Median Particle Size, Microns | Rigid PVC | Flexible PVC | |

| Kemgard®911C | 3.3 | Zinc Molybdate / Magnesium Silicate Compound |

● | ● |

| Kemgard®1100 | 2 | Zinc Molybdate / Magnesium Silicate Compound |

● | ● |

| Kemgard®MZM | 2 | Zinc Molybdate / Magnesium Hydroxide Compound |

● | |

| Kemgard®605 | Zinc Molybdate / Magnesium Hydroxide Compound |

● | ● | |

| Kemgard®620 | Zinc Molybdate / Magnesium Hydroxide Compound |

● | ● | |

| Kemgard®631 | Zinc/aluminum compound | ● | ● | |

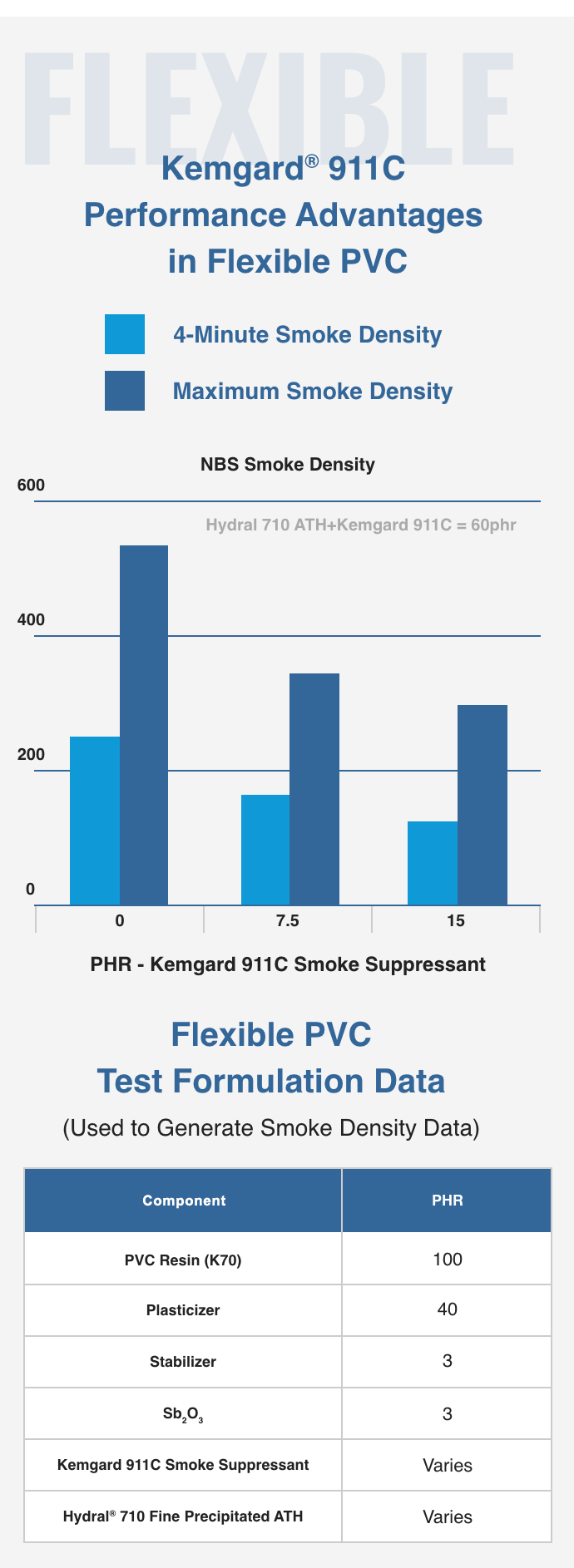

Here's What Makes Kemgard® Smoke Suppressants A Perfect Fit In Rigid And Flexible PVC

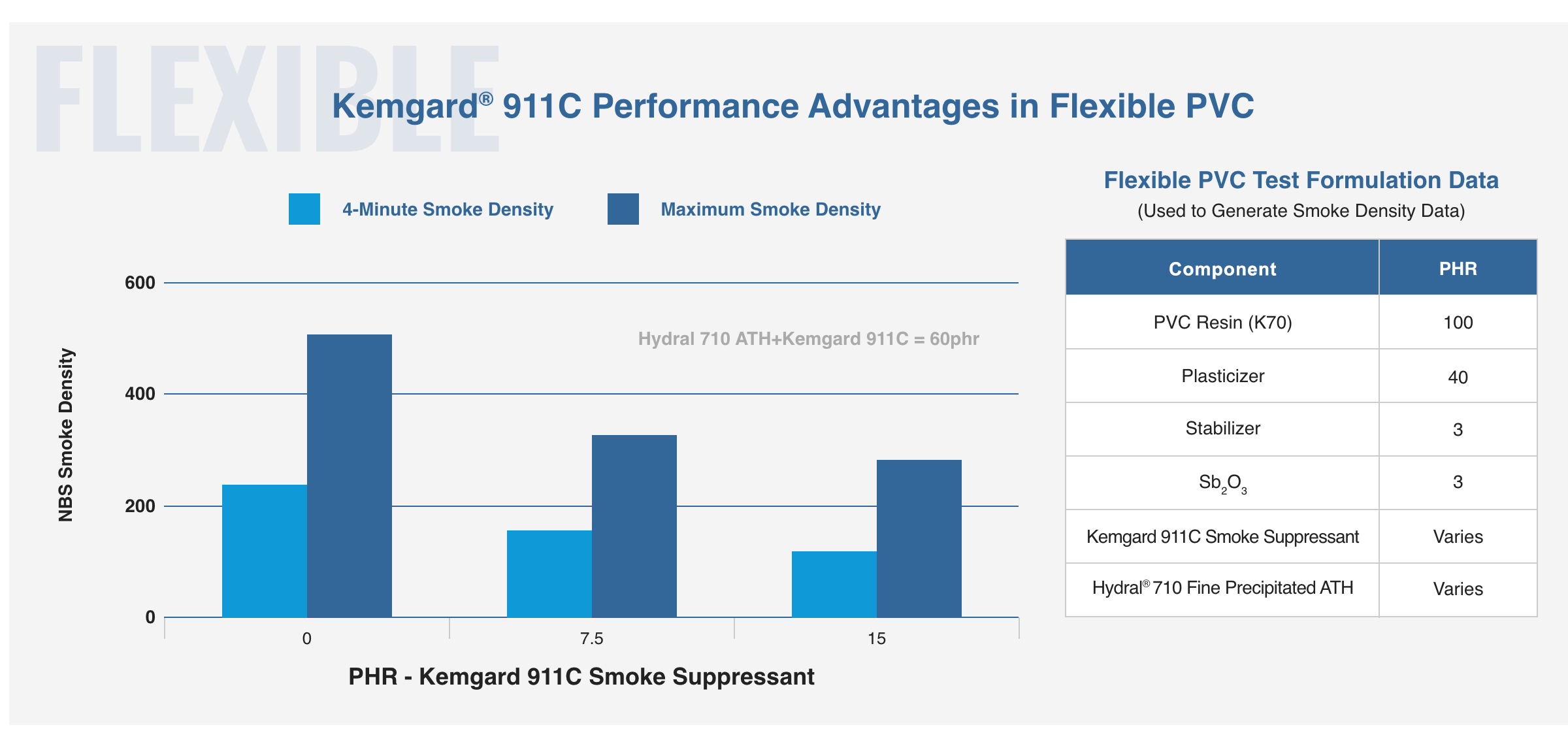

- Kemgard® works as a synergist between aluminum hydroxide (ATH) and magnesium hydroxide (MDH) to achieve the targets of flame retardancy and smoke generation levels.

- Kemgard® can partially replace AOM and antimony oxide to achieve the control-goal of smoke suppress. In addition to costs reduction, the use of antimony oxide minimizes regulatory restrictions.

Kemgard® Highly Efficient Fire Retardants and Lubricants for Printed Circuit Boards

Kemgard® is the ideal solution to improve the properties in printed circuit boards by implementing flame retardance. These chemically affect the formation of organic chars that effectively isolate resin from heat and oxygen sources and reduce heat and smoke generation.

In addition, Kemgard® molybdic acid provide lubricity with printed circuit board in drilling process.

Grade 4 for printed circuit boards improves chemical and physical properties and meets the most stringent flame retardant requirements.

| Kemgard® Products (White Powder Appearance) | Median Particle Size, Microns | Component |

|---|---|---|

| Kemgard®911C | 3.3 | Zinc Molybdate / Magnesium Silicate Compound |

| Kemgard®911B | 1.0 | Zinc Molybdate / Zinc Oxide Compound |

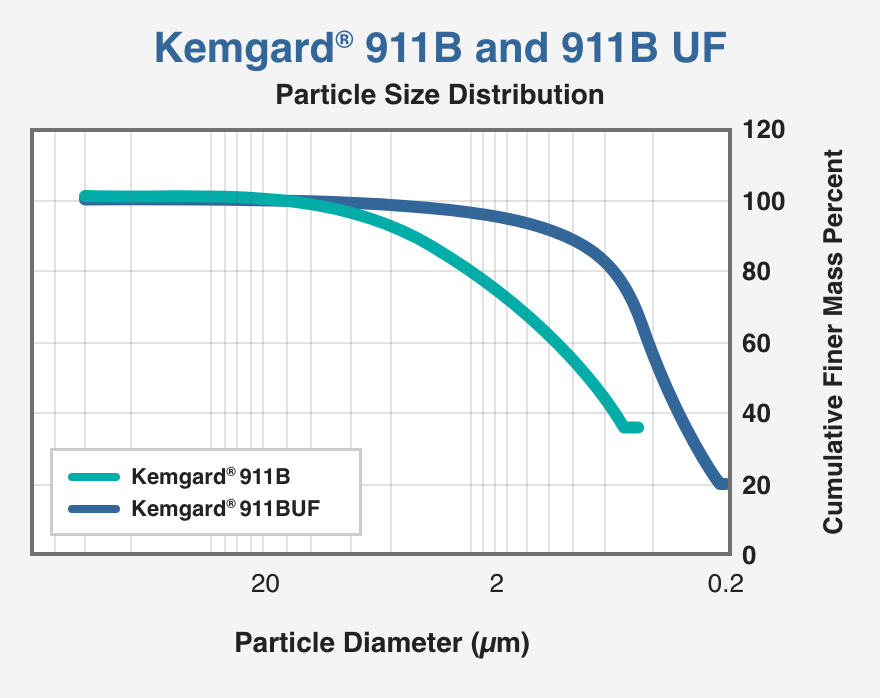

Kemgard® 1100 and grade 2 of Kemgard® Ultrafine (UF) fine powder in Kemgard® 911B UF offer the following key properties

- Ultra fine powder

- Maximum particle size 10μm or less

- High Surface Area

- Improvement physical properties of compounds

- Improvement of forming char function

- Excellent surface quality

| Kemgard® Products (White Powder Appearance) | Median Particle Size, Microns | Top Particle Size, Microns | Component |

|---|---|---|---|

| Kemgard®1100 | 2.0 | < 10 | Zinc Molybdate / Magnesium Silicate Compound (Fine powder) |

| Kemgard®911B-UF | 0.3 | < 5 | Zinc Molybdate / Zinc Oxide Compound (Fine powder) |

Technical information is based on the English catalog of Huber, Inc. in US.

Please visit Huber's website to see the original catalog.

Kemgard® / Flame retardant and smoke suppressant

Please contact us for details.

Contact Us

Inquiry to Products, Services and/or Business