Surface Finishing Chemicals Business Division

Comprehensive supports to surface finishing chemicals businesses

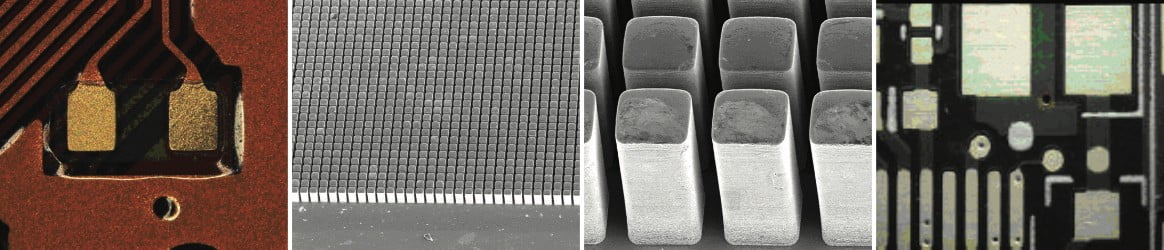

JX Metals Trading conducts the own plant to manufacture surface finishing chemicals, used for semiconductor, electronic components, printed circuit board and decorative goods and supply them to customers.

In alignment with group companies chiefly in Southeast Asia, we offer technical supports and stock sales on a timely manner.

Responce to customers' requirements through works of development, testing and analysis

As the development-oriented plant, we focus on new development of surface finishing chemicals. Based on our long experiences and accumulated technical data, we would offer new and the customized products. We provide services of testing and analysis by our own evaluation equipments and arrange engineers' visit to a customer's site.

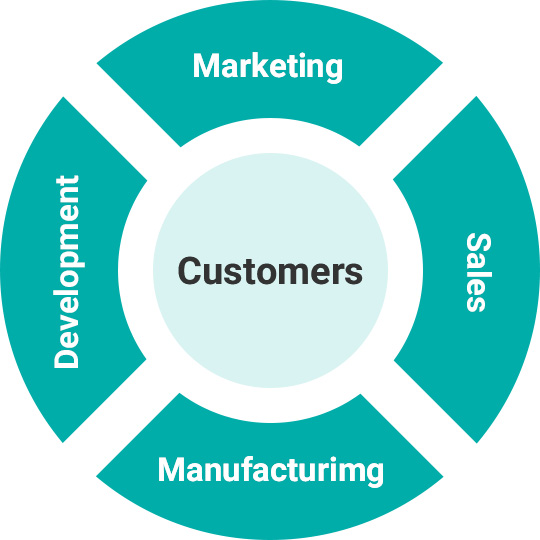

Solutions proposed from four insights

Products Line-up

- Electroless Plating Chemicals for PWB/FPC

- Degreasing~Plating~Sealing treatment (Ni-Pd-Au,Ni-Au)

- Electroless Plating Chemicals for industrial parts

- Middle~High Phosphorous/Excellent for anti-corrosion property (Ni,Sn)

- Lead Frame Chemicals

- CPO*1 / EBP*2 / Improving adhesion (Cu,Ni,Sn,Au,Ag)

- Functional Surface Finishing Chemicals (Anti-tarnish for metal)

- Anti-rust for metal / Improving adhesion (Cu,Ni,Sn,Au,Ag)

- Electro Plating Chemicals (Ni,Sn,Cu)

- Plating solutions and Metal compounds for plating

- Precious Metal Plating Chemicals (Au,Ag,Rh,Ru)

- Plating solutions for Industrial and decorative usage

- *1 CPO:Copper Peel Off

- *2 EBO:Epoxy Bleed Out

Takatsuki Plant

Development-oriented plant to manufacture surface finishing chemicals over 100 years

Operation Policy

(1) Comprehensive supports to surface finishing chemicals business

- Consistently responding to customers' requirements of development, manufacturing, analysis and failure analysis

(2) Developing and manufacturing products from customers' perspective

- Inviting customers to the plant and solving a problem from our empirical point of views

(3) Arranging engineers' visit to support making-up bath and conditioning

- Dispatching engineers to domestic and overseas customers' places for general supports

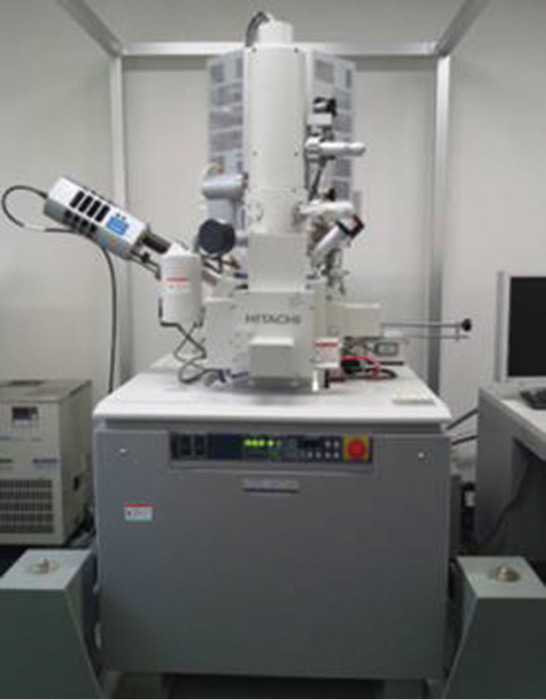

Assessment & analysis equipments

- Surface monitoring in cross section

-

- Field-emission-type scanning electron microscope (Hitachi, SU-8020)

- Ion-sputter coating machine (Hitachi, E101)

- Energy-dispersive X-ray analyzer (HORIBA, XMAX-370)

- XPS X-ray photoelectron spectrometer (ULVAC-PHI, PHI5000 Versa Probe III)

- Cross section polisher (JEOL, IB-19500CP)

- Stereo microscope(Leica Microsystems, M125C)

- 3D Surface Profiler(KEYENCE, VK-X1000)

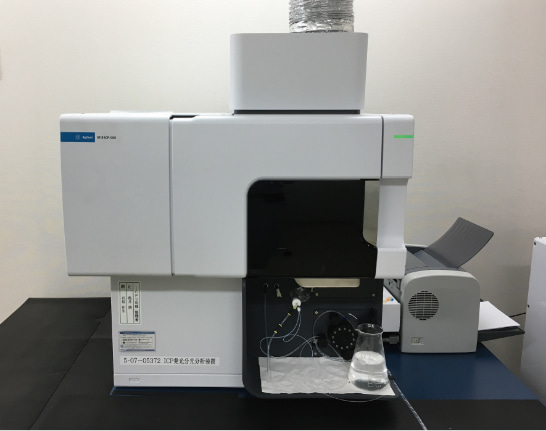

- Concentration analysis

-

- ICP high-frequency plasma emission spectrometer(Agilent, 5110 ICP-OES/SII SPS-3520-DD)

- Atomic absorption spectrometer (Thermo Electron, iCE3300)

- UV and visible-spectrum spectrophotometer (Shimadzu, UV-2600)

- High-performance liquid chromatograph (Nippon Waters, ACQUITY)

- Capillary electrophoresis analyzer (Otsuka Electronics, Agilent7100)

- Total organic carbon analyzer (Shimadzu, TOC-V)

- Fourier-transform infrared spectrophotometer (JASCO, FT-IR4600)

- Gas chromatograph (Agilent, 7890B)

- Other experimental equipments

-

- Bondtester (Dage, Series4000)

- Solder reflow oven (Japan Pulse, RF-330)

- Solder checker (Rhesca, SAT-5100)

- X-ray fluorescence coating thickness-measuring instrument (Fischer, X-RAY XDV-µ)

- Dynamic ultramicro hardness tester (Shimadzu, DUH-211)

- Salt spray/CASS test instrument (Suga Test Instruments, STP-90)

- Constant temperature and constant humidity monitor (Nagano Science, LH33-12M)

- MIT-type folding endurance tester (Yasuda Seiki Seisakusho, No. 307 DW-1)

- Precision universal tester (Shimadzu, AGS-X)

- Electrical contact simulator (Yamazaki Seiki Seisakusho, CRS-113-Au)

- Contact Angle Meter(Kyowa Interface Science, DMe-210)

Others