Heat-resistant copper anti-tarnish agent (AT-4)

Test results of copper oxide film peeling

| 280℃ | 300℃ | 320℃ | 340℃ | 360℃ | 380℃ | 400℃ | |

|---|---|---|---|---|---|---|---|

| Untreated |

|

|

|

|

|

|

|

| Peeling area ratio(%) | 0 | 0 | 10 | 20 | 50 | 90 | 100 |

| AT-4 |

|

|

|

|

|

|

|

| Peeling area ratio(%) | 0 | 0 | 0 | 0 | 0 | 1 | 5 |

Copper material: C194 alloy + copper strike plating (0.2 μm)

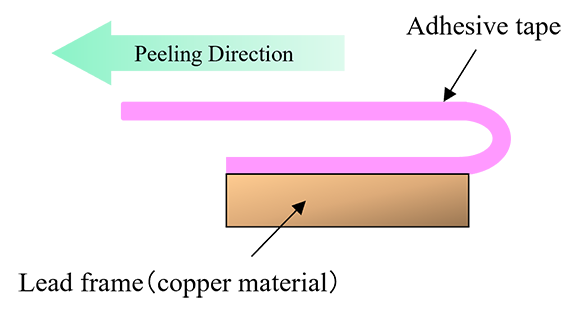

Test method of

copper oxide film peeling (tape peeling)

- 1Heat on a hot plate for five minutes (280 to 400°C)

- 2Hold the adhesive tape at an angle of 180° to the surface and peel it off.

- 3Calculate the ratio of copper oxide film transferred to the adhesive tape from the overall area ratio.

Features

- Contains a new component with higher heat resistance than general copper anti-tarnish agents (benzotriazole).

- Forms a dense monomolecular film that has a high affinity for copper.

- The formation of monomolecular film acheives both wire bondability and solderability.

- Copper oxide film peeling resistance comparable to conventional silver potassium cyanide (PSC) additive type.

- In addition to the above properties, it is also highly resistant to moisture and heat discoloration.

Main applications

- IC lead frames

- Copper bonding wires

- Conductive copper paste

- Copper bump joints

Please contact us for details.

Contact Us

Inquiry to Products,

Services and/or Business